| Recently I've been reading quite a lot regarding resistance to change both on personal level and organizational level: Individuals don't like the unknown, it might pose a risk therefore they resist change. The same principle seems to apply to organizations as well. Nobody would argue that the world is changing however. So what is driving all the changes around us? In my view there has to be some external incentives to change. Either the changes are related to making life more comfortable |

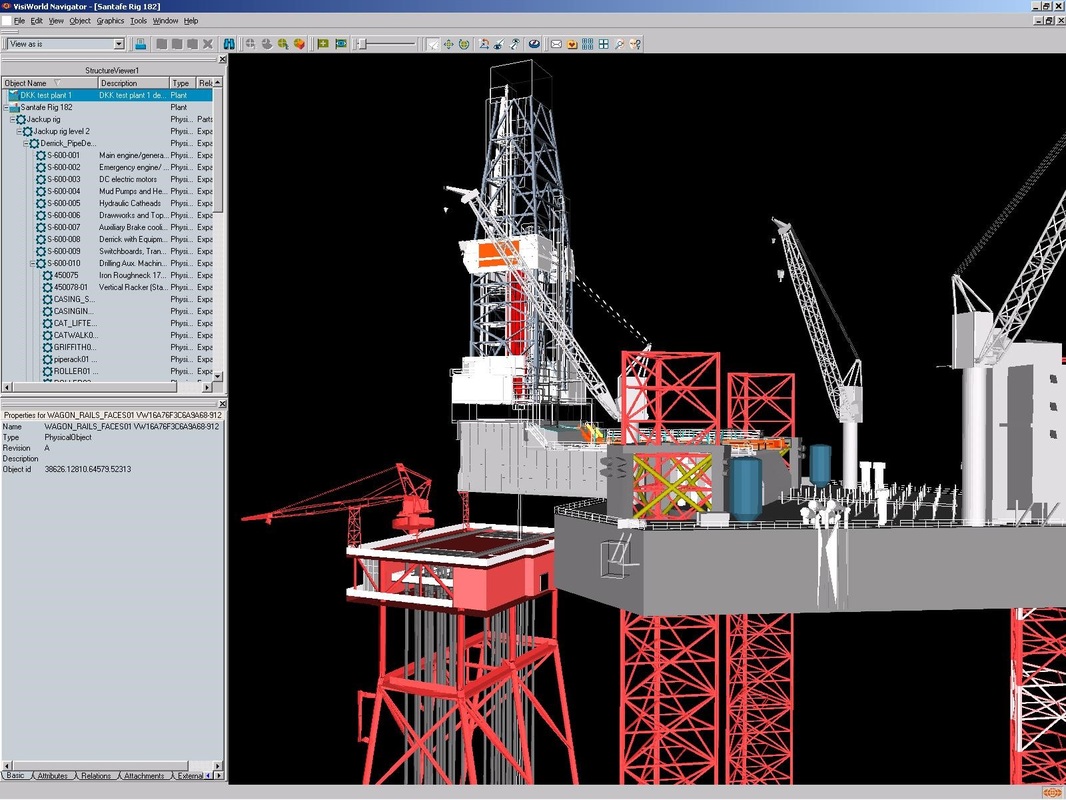

15 years ago I was part of an initiative called VisiWorld. The vision was using a PLM platform as a means to manage all data regarding a Facility from early planning through engineering, construction, operations and maintenance. Our Virtual Reality technology was used to visualize the vast amount of data through all lifecycle stages. The idea was that VisiWorld would integrate to a number of engineering and planning tools to create an information backbone where technical information could be consolidated, visualized and managed in a 3D world as well as structured data in 2D object structures.

To ensure full interoperability the data model and integrations were based on POSC/CAESAR (Later merged into ISO 15926)

The main objective was to reduce cost by making information consolidation and traceability easier, and to eliminate all the costly information handovers between EPC (Engineering Procurement and Construction) companies, product companies and ultimately Owner/Operator in capital projects. This would be achieved by working in a fully integrated environment.

I think our project manager said it best when asked by a reporter actually months before we went under. The reporter asked: “What if this product does not become a success, what would the inscription on its tombstone be?” Our project manager thought for a while before responding: “Too much, too early”.

That was of course a sad ending to VisiWorld, but not to this story.

I moved on to work with PLM in many different industries, but could never really forget about the concepts and ideas.

10 years later I again found myself building a “Plant/Facility Lifecycle Management” solution on top of a PLM system. It was nowhere near as ambitious as VisiWorld, but most of the concepts were there. This time the visualization engine was based on XMpLant and ISO 15926. What I found really interesting was that the ideas from 10 years before were still considered innovative and new by the industry. The oil&gas companies we approached with this solution were interested and agreed that this was the necessary way forward, but I still got the feeling that it was “Too much, too early”.

The incentives to change were just not strong enough.

Now 15 years after our initial Facility Lifecycle Management project I find myself having helped two organizations implement some of the thoughts and concepts. Ironically, neither is in the Oil & Gas industry.

Why is that?

Change happens very slowly, unless there are very strong incentives. Those incentives have not been there before in the Oil & Gas industry. However they could very well be coming now, if the oil price stays as low as it is currently or even lower for years to come….

Other industries have been forced to change the way they act and operate due to shrinking margins and competition from others.

Oh and when I say shrinking margins it is as in shrinking so much it means that either the company finds a better way of managing projects/products or die

Some points to ponder

Bjorn Fidjeland

Advanced Control – Drilling & Well AS has copyright to the images used in this post, but has graciously allowed me to use them.

RSS Feed

RSS Feed