Image courtesy of European Spallation Source ERIC

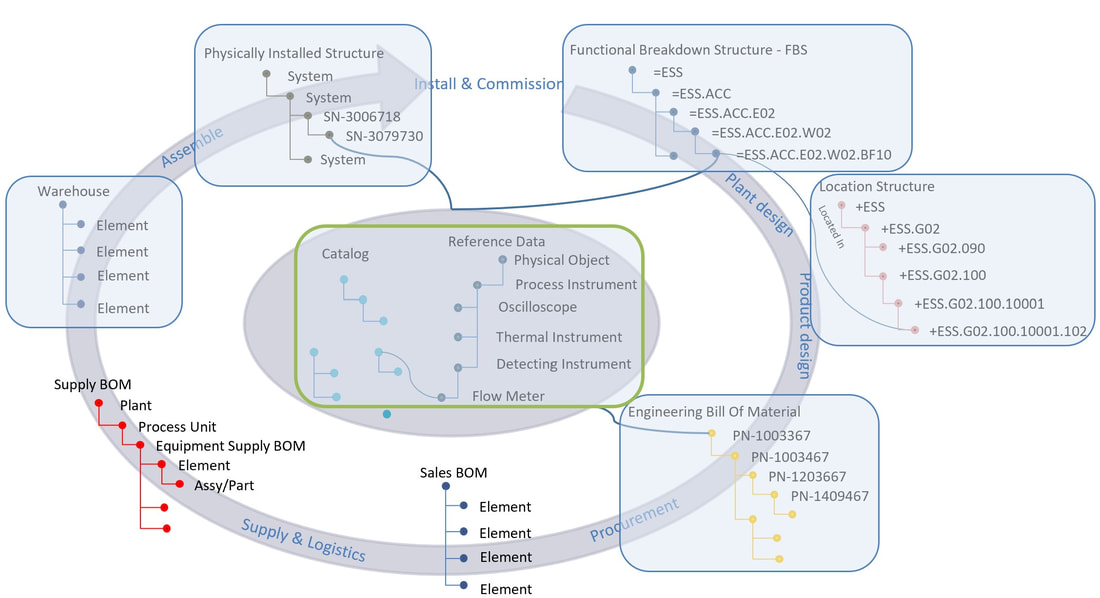

In previous chapters we’ve discussed the different data and information structures that needs to be in place in order to support a capital facilities project like the European Spallation Source from engineering through operations, maintenance and ultimately decommissioning.

Structured data is excellent, but wouldn’t it be even better to also have aligned definitions across data-structures and tools?

It certainly would, so in this chapter we’re going to look into what has been done at ESS to achieve interoperability across both data structures and software tools.

If you would like to read previous chapters first before we take a deeper dive, you can find them all here: Archive

In previous chapters we’ve discussed the different data and information structures that needs to be in place in order to support a capital facilities project like the European Spallation Source from engineering through operations, maintenance and ultimately decommissioning.

Structured data is excellent, but wouldn’t it be even better to also have aligned definitions across data-structures and tools?

It certainly would, so in this chapter we’re going to look into what has been done at ESS to achieve interoperability across both data structures and software tools.

If you would like to read previous chapters first before we take a deeper dive, you can find them all here: Archive

The figure above shows that Tag’s, Parts (in EBOM’s) and Installed Assets all use the same reference data library to obtain class names and attributes, meaning that a centrifugal pump is called exactly that across all structures as well as in different authoring tools, the PLM system and the Enterprise Asset Management system. Furthermore, they share the same attribute names and definitions including unit of measures.

Several years ago, it was decided to use ISO 15926 as a reference data library. We were able to obtain an export of the RDL (Reference Data Library) by the excellent help of then POSC Caesar Services and imported ISO 15926 part 4 into the PLM platform. Easy right? Well, not quite. We discovered that we now had more than 7000 classes beautifully structured and about 1700 attributes. However, none of the attributes were assigned to the main classes as the attributes were all defined as sub classes of a class called property.

Several years ago, it was decided to use ISO 15926 as a reference data library. We were able to obtain an export of the RDL (Reference Data Library) by the excellent help of then POSC Caesar Services and imported ISO 15926 part 4 into the PLM platform. Easy right? Well, not quite. We discovered that we now had more than 7000 classes beautifully structured and about 1700 attributes. However, none of the attributes were assigned to the main classes as the attributes were all defined as sub classes of a class called property.

Figure 2. Image courtesy of European Spallation Source ERIC

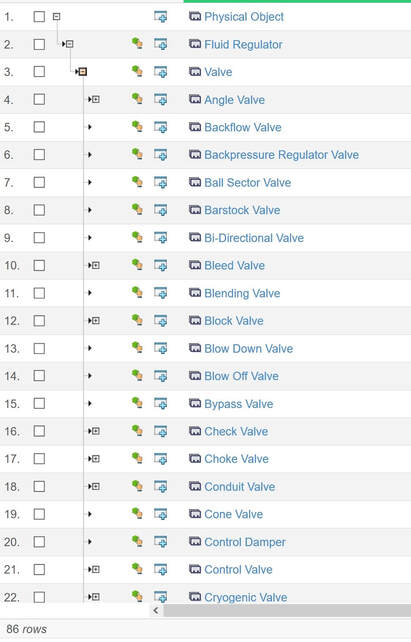

Figure 2 shows a small portion of the reference data library.

What this in essence meant was that you could select a class to be used for a Tag, Part or an Asset and it would be clear that it was a Choke Valve across all entities, but the entities would not have any attributes defined.

The solution to this problem was to form a cross discipline reference data group whose mandate is to assign needed attributes for ESS to the classes. It was soon discovered that the standard did not contain everything needed to describe a research facility, so the group also received a mandate to define new classes and attributes whenever needed. The reference data group met every week for the first two years, but now, it meets every second week.

The group is also tasked with defining letter codes for all classes to be used at ESS according to the standard ISO 81346 which is the chosen tagging standard.

After every meeting any new classes, attributes and letter codes are deployed to the master reference data library in the PLM platform. The library serves as a common data contract across tags, parts and assets meaning that every entity get the same set of attributes and more importantly, identical names and definitions. This is also enforced across different software tools, rendering integration between the tools a lot easier as the need for complex mapping files disappears.

Figure 2 shows a small portion of the reference data library.

What this in essence meant was that you could select a class to be used for a Tag, Part or an Asset and it would be clear that it was a Choke Valve across all entities, but the entities would not have any attributes defined.

The solution to this problem was to form a cross discipline reference data group whose mandate is to assign needed attributes for ESS to the classes. It was soon discovered that the standard did not contain everything needed to describe a research facility, so the group also received a mandate to define new classes and attributes whenever needed. The reference data group met every week for the first two years, but now, it meets every second week.

The group is also tasked with defining letter codes for all classes to be used at ESS according to the standard ISO 81346 which is the chosen tagging standard.

After every meeting any new classes, attributes and letter codes are deployed to the master reference data library in the PLM platform. The library serves as a common data contract across tags, parts and assets meaning that every entity get the same set of attributes and more importantly, identical names and definitions. This is also enforced across different software tools, rendering integration between the tools a lot easier as the need for complex mapping files disappears.

Figure 3. Image courtesy of European Spallation Source ERIC

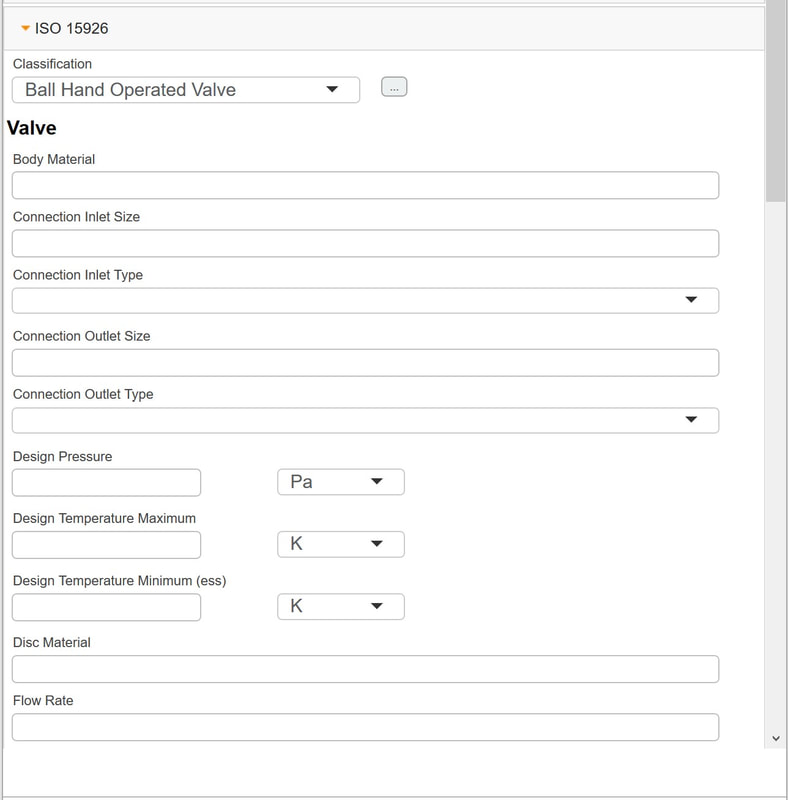

Figure 3 shows some of the attributes that have been associated to the class Valve. As the PLM platform supports inheritance of attributes in class libraries, special care is taken with respect to adding attributes at an appropriate level so that the attributes are valid for all sub classes.

Figure 3 shows some of the attributes that have been associated to the class Valve. As the PLM platform supports inheritance of attributes in class libraries, special care is taken with respect to adding attributes at an appropriate level so that the attributes are valid for all sub classes.

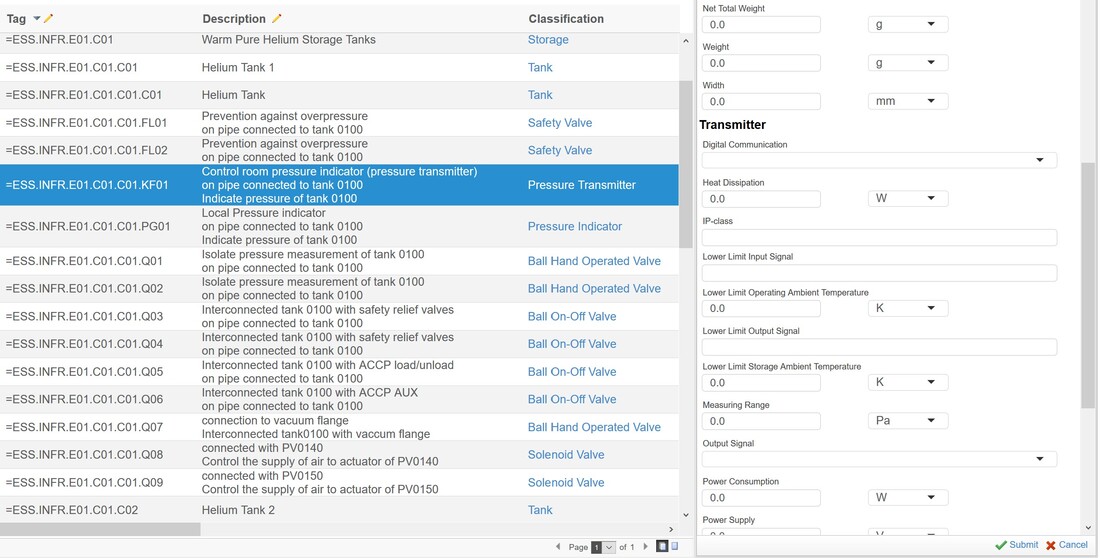

Figure 4. Image courtesy of European Spallation Source ERIC

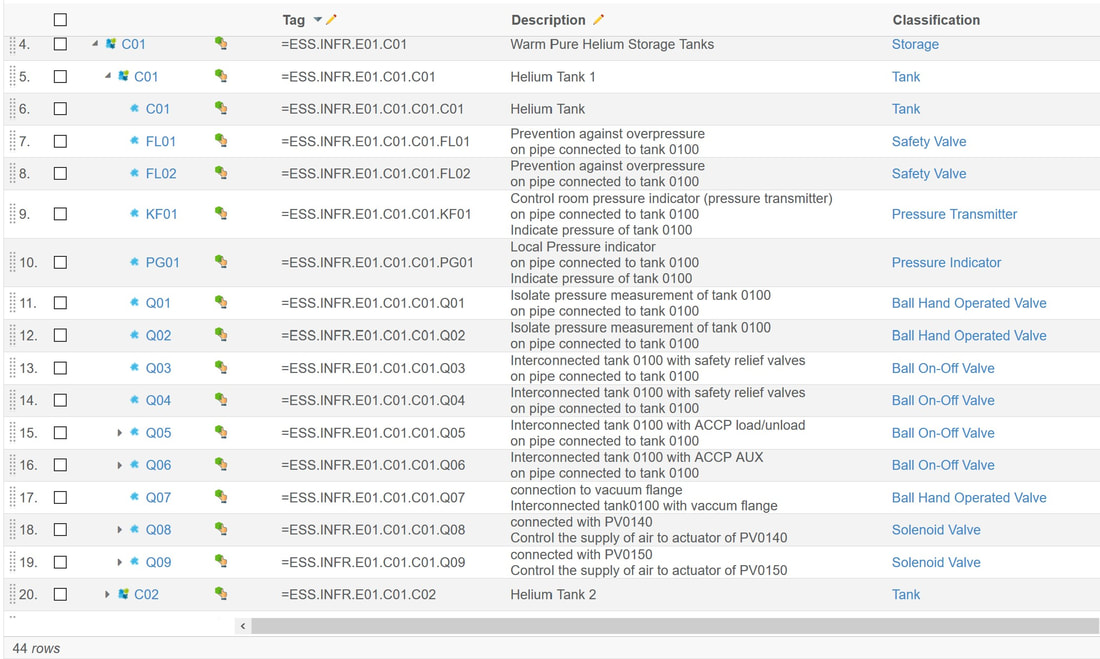

Figure 4 is from the functional breakdown structure where some of the functional objects (tags) are listed. Please note the classification column indicating which class from the reference data library has been used to define attributes to each specific tag.

Figure 4 is from the functional breakdown structure where some of the functional objects (tags) are listed. Please note the classification column indicating which class from the reference data library has been used to define attributes to each specific tag.

Figure 5. Image courtesy of European Spallation Source ERIC

Let’s examine one of the tags a bit closer. Figure 5 shows some of the attributes for the specific pressure transmitter selected (but without production data).

The same kind of information is available on any part selected to realize the tag requirements and ultimately on the delivered asset itself that was installed in the facility to fulfill the tag’s requirements.

The challenges described in this article are of course not unique to ESS, and several companies have done similar exercises or defined their own proprietary master data. The problem with all of them is that it becomes reference data libraries that are unique to a specific project or for one company only and thereby not solving interoperability problems between companies participating in the value chain of a capital facilities project.

I’m happy to see that initiatives like CFIHOS (Capital Facilities Information HandOver Specification, now that’s a tongue twister) seems promising and are worth checking out for anybody thinking about embarking on a similar journey, however for ESS it was never an option as we needed usable reference data fast.

It is my hope that this article can serve as inspiration for other companies as well as software vendors. I also want to express my gratitude to the European Spallation Source and to Peter Rådahl, Head of Engineering and Integration department in particular for allowing me to share this with you.

Bjorn Fidjeland

Let’s examine one of the tags a bit closer. Figure 5 shows some of the attributes for the specific pressure transmitter selected (but without production data).

The same kind of information is available on any part selected to realize the tag requirements and ultimately on the delivered asset itself that was installed in the facility to fulfill the tag’s requirements.

The challenges described in this article are of course not unique to ESS, and several companies have done similar exercises or defined their own proprietary master data. The problem with all of them is that it becomes reference data libraries that are unique to a specific project or for one company only and thereby not solving interoperability problems between companies participating in the value chain of a capital facilities project.

I’m happy to see that initiatives like CFIHOS (Capital Facilities Information HandOver Specification, now that’s a tongue twister) seems promising and are worth checking out for anybody thinking about embarking on a similar journey, however for ESS it was never an option as we needed usable reference data fast.

It is my hope that this article can serve as inspiration for other companies as well as software vendors. I also want to express my gratitude to the European Spallation Source and to Peter Rådahl, Head of Engineering and Integration department in particular for allowing me to share this with you.

Bjorn Fidjeland

RSS Feed

RSS Feed