- Equipment manufacturers, where digitalization can be merged with Internet Of Things to create completely new service offerings and relationships with the customers

- Capital projects EPC’s and operators, where a digital representation of the delivery can be handed over as a “digital twin” to the operator , and where the operator can use it and hook it up to EAM or MRO solutions to monitor the physical asset real-time in a virtual world. The real value for the operator here is increased up-time and lower operational costs, whereas EPC’s can offer new kinds of services and in addition mitigate project risks better.

- Construction industry, where the use of VDC (Virtual Design & Construction) technology can be extended to help the facility owner minimize operational costs and optimize comfort for tenants by connecting all kinds of sensors in a modern building and adjust accordingly.

“Digitalization is the use of digital technologies to change a business model and provide new revenue and value-producing opportunities; it is the process of moving to a digital business.” (Source: Gartner)

…The process of moving to a digital business….

The digitalization strategies of most of the companies I’ve been working with focuses on the creation of new services and revenue possibilities on the service side of the lifecycle of a product or facility, so AFTER the product has been delivered, or the plant is in operation.

There is nothing wrong with that, but if the process from design through engineering and manufacturing is not fully digitalised (by that I do not mean documents in digital format, but data as information structures linked together) then it becomes very difficult to capitalize on the promises of the digitalization strategy.

Consider 2 examples

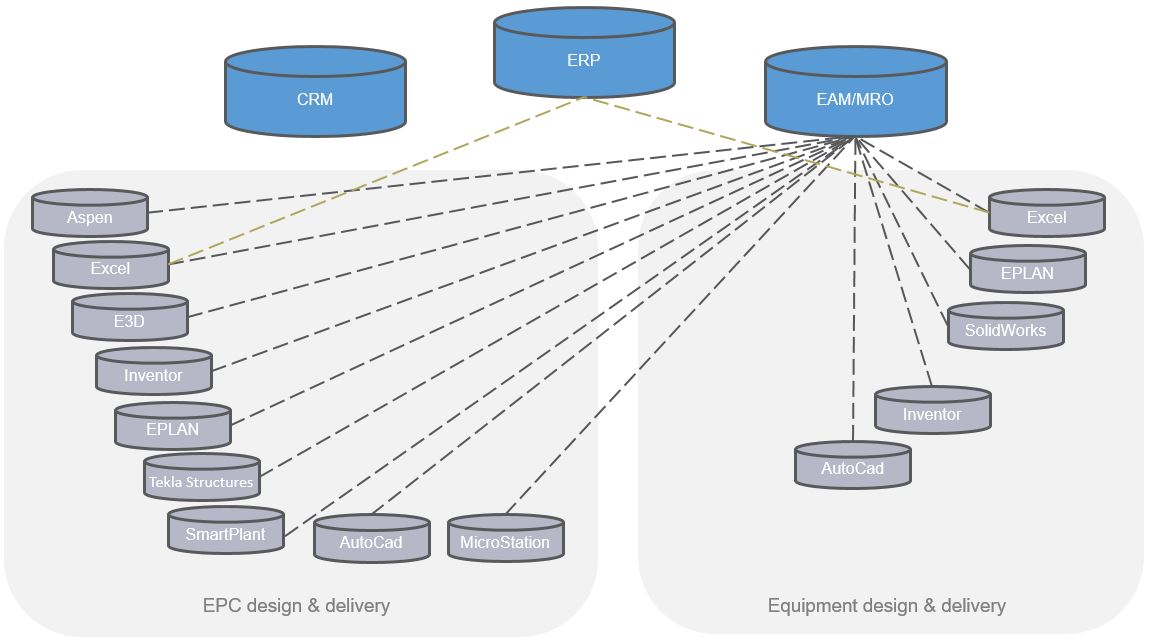

Figure 1 describes a scenario where design and engineering tools work more or less independently and where the result is consolidated in documents or excel before communicated to ERP. This is the extreme scenario to illustrate the point, and most companies have some sort of PDM/PLM or Engineering Register to perform at least partial consolidation of data before sending to ERP. However I often find some design or engineering tools operating as “islands” outside the consolidation layer.

So if we switch viewpoint to the new digital service offering promoted to end customers. What happens when a sensor is reporting back a fault in the delivered product? The service organization must know exactly what has been delivered, where the nearest spare parts are, how the product is calibrated etc. to quickly fix the problem with a minimum use of resources in order to make a profit and to exceed customer expectation to gain a good reputation.

How likely is that to happen with the setup in figure 1?

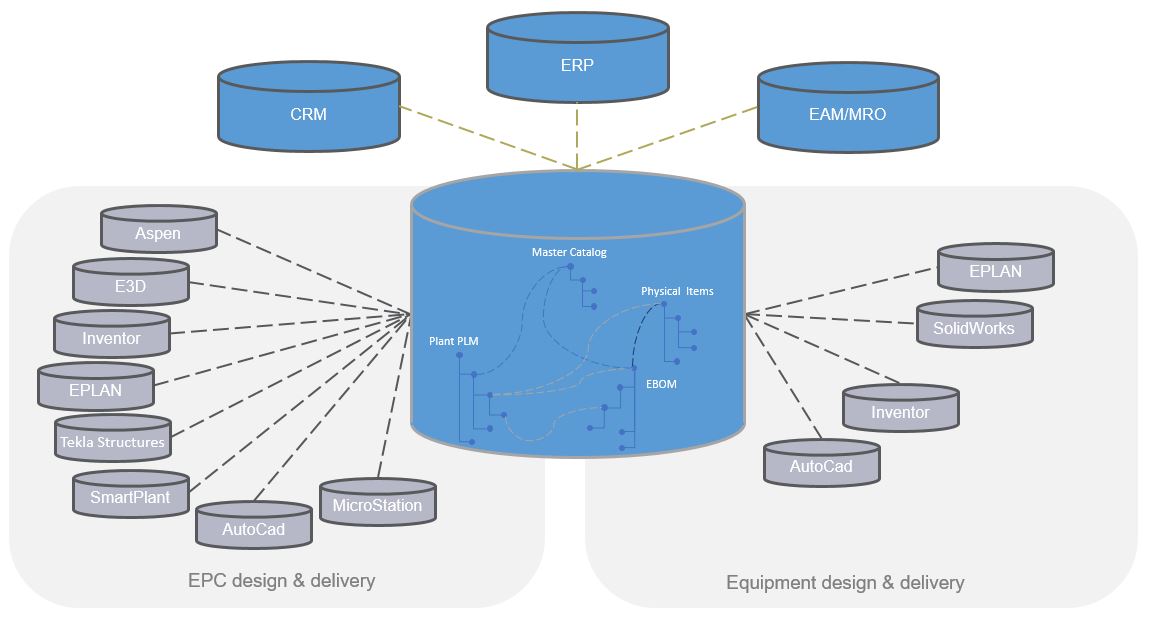

The setup in figure 2 describes a situation where design and engineering information is consolidated together with information regarding the actually delivered physical products. This approach does not necessarily dictate that the information is only available in one and only one software platform, however the essence is that the data must be structured and consolidated.

Again let’s switch viewpoint to the new digital service offering promoted to end customers. What happens when a sensor is reporting back a fault in the delivered product?

When data is available as structured and linked data it is instantly available to the service organization, and appropriate measures can be taken while informing the customer with accurate data.

My clear recommendation is that if you are embarking on a digitalization journey to enhance your service offering and offer new service models, then make sure you have a solid digital foundation to build those offerings on. Because if you don’t it will be very difficult to achieve the margins you are dreaming of.

Bjorn Fidjeland

The header image used in this post is by kurhan and purchased at dreamstime.com

RSS Feed

RSS Feed